How the DISCUS Interface Approach can streamline your First Article Inspection

Business Problem

For many part suppliers, the CMM generates the bulk of the results data for the First Article Inspection. However, it is time-consuming and error-prone to transcribe the digital data generated from the CMM into the specific customer or industry FAI forms.

Example: Aerospace Part Supplier in Arizona

- They create 20 CMM new part programs per year

- It costs roughly $1,500 per part for CMM programming

- The CMM programming is sometimes coordinated with FAI ballooned drawing

- Time-consuming manual extraction of CMM results and mapping to characteristics for FAI

This is where the DISCUS Interface Approach steps in and makes the extraction of CMM results for First Article inspection an efficient and cost effective process.

Key Acronyms

To begin understanding how this process works, consider these important terms.

To begin understanding how this process works, consider these important terms.

- DMSC – Dimensional Metrology Standards Consortium. The industry organization for CMM-related activities.

- DMIS – Dimensional Measurement Interface Specification. DMIS defines a neutral language for communication between software and dimensional measurement equipment (DME). Its purpose it to convey the product and equipment definitions along with the process and reporting information necessary to perform dimensional measurements. It is the most common ‘language’ for controlling CMMs.

- DML – Dimensional Markup Language. It is the theoretical standard for formatting CMM outputs/reports.

- eQuiPP – Exchange of Quality Measurement Process Plans Specification. This is a new, early stage standard from DMSC, but it is not really going anywhere

- Q-DAS – Proprietary European SPC data transfer format

- QMD – Quality Measurement Data. The standard developed by auto industry and NIST.

- DME – Dimensional Measuring Equipment. This is the term for the actual CMM or gauging equipment.

CMM Process Overview

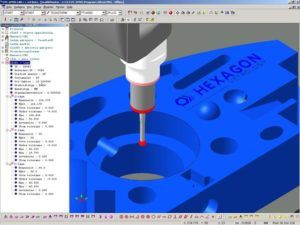

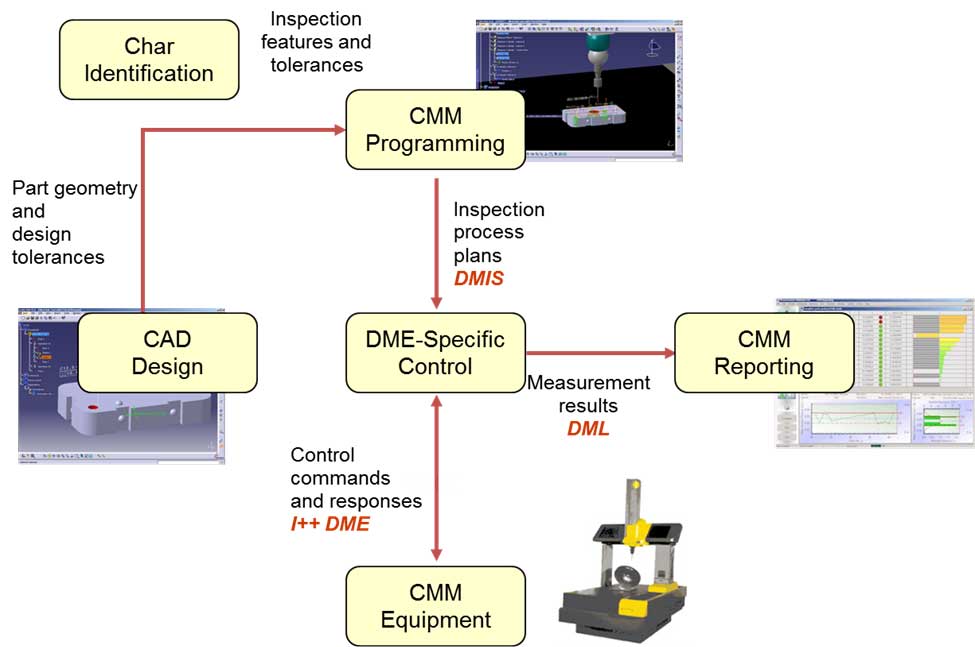

The process begins with the CAD design in which the part geometry and design tolerances are defined. This is the point of characteristic identification and when inspection features and tolerances are incorporated into the CMM programming. The CMM Programmer translates these inspection process plans into DMIS so as to control the DME, which carries out the measurements. The results of said inspection are output in CMM reporting software. See the flow chart below for more information.

CMM Interface

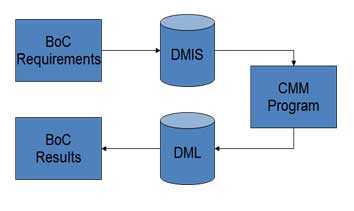

Consider this diagram for more detail on how DISCUS software streamlines the process for First Article Inspection. The Bill of Characteristics requirements are defined to help DMIS to program you CMM hardware. Once the measurements are taken, DISCUS software takes the output results in DML. These results are compared with the Bill of Characteristics to verify that the requirements are met.